As global demand for renewable energy continues to rise, floating solar (Floating PV or FPV) has emerged as a rapidly expanding segment of the PV industry. By utilizing water surfaces instead of land, FPV systems help reduce water evaporation, increase module efficiency through natural cooling, and optimize land resource utilization.

Within these systems, the floater is a critical component. The choice of floater material directly determines a plant’s structural stability, service life, safety, and overall lifecycle cost.

So, what materials are commonly used for FPV floaters today? And how do their properties differ across application scenarios? This article provides a comprehensive breakdown.

The Role of the Floater in Floating PV Systems

In any floating PV installation, the floater performs several essential functions:

- Supports the PV array and provides buoyancy and stability

- Adapts to water-level fluctuations to maintain structural integrity

- Withstands UV exposure, waves, temperature variations, and long-term environmental stress

- Ensures a design life of 20–25 years or longer

- Serves as a pathway or structural element for maintenance and interconnection

Therefore, floater materials must offer strong mechanical properties as well as resistance to corrosion, aging, UV radiation, and environmental degradation—while maintaining environmental compatibility.

Main Types of Floater Materials for Floating Solar

1. High-Density Polyethylene (HDPE) — The Industry Standard

HDPE is the most widely used material for FPV floaters and currently dominates the market.

Key characteristics:

- Outstanding corrosion resistance

- Excellent UV and aging resistance

- Strong impact and low-temperature performance

- Environmentally safe and compatible with natural water bodies

Advantages:

- Typical design life of 20–25 years

- Lightweight and easy to install

- Balanced cost and performance

Application scenarios:

- Reservoirs and lakes

- Fishery–solar hybrid projects

- General inland floating installations

HDPE’s maturity, reliability, and cost efficiency make it the default choice for most FPV projects.

2. Polypropylene (PP)

PP is another common engineering plastic and is sometimes used for floaters or auxiliary components.

Key characteristics:

- Higher rigidity

- Excellent chemical resistance

- Lower density, providing higher buoyancy

Advantages:

- Strong compressive properties

- Suitable for components requiring higher stiffness

Limitations:

- Lower low-temperature resistance compared with HDPE

- Slightly weaker long-term outdoor aging performance

Application scenarios:

- Regions with stable temperatures

- Modules requiring additional structural rigidity

3. Fiber-Reinforced Plastic (FRP)

FRP is a high-performance composite offering superior strength and customization potential.

Key characteristics:

- High structural strength and stability

- Excellent resistance to corrosion and salt spray

- Highly customizable for complex shapes

Advantages:

- Suitable for harsh or specialized environments

- Long service life with minimal maintenance

Limitations:

- Higher material and production costs

- Longer manufacturing timeline

Application scenarios:

- Offshore floating PV

- High-corrosion, high-wave environments

- Large platforms or maintenance walkways

4. Aluminum Alloy Floater Structures

Some premium FPV systems use aluminum frames combined with sealed air chambers as buoyancy modules.

Key characteristics:

- Lightweight with high mechanical strength

- Good corrosion resistance

- Highly recyclable material

Advantages:

- High safety factor

- Seamless integration with aluminum PV mounting structures

- Suitable for deeper water and rougher conditions

Limitations:

- Higher costs

- Requires strict welding and fabrication standards

Application scenarios:

- Offshore and large-reservoir projects

- Installations requiring high load-bearing performance

5. Steel Floaters (Galvanized Steel / Stainless Steel)

Although less common, steel floaters offer unique advantages in extreme engineering conditions.

Key characteristics:

- Very high strength and rigidity

- Excellent impact resistance

Advantages:

- Capable of withstanding heavy wave loads

- Superior structural stability

Limitations:

- Heavy weight

- High requirements for corrosion protection

- Higher maintenance and total cost

Application scenarios:

- Offshore severe wave conditions

- Mega-scale engineering platforms

6. Composite Floaters (PE + Foam / EVA / PU, etc.)

Composite floaters combine a PE outer shell with internal foam or buoyancy cores.

Structure:

- PE external shell

- EVA, PU foam, or other buoyant fillers inside

Advantages:

- High buoyancy

- Enhanced impact resistance

- Suitable for areas with significant water-level fluctuation

Limitations:

- Slightly higher cost

- More complex maintenance

Application scenarios:

- High-buoyancy requirements

- Walkway floaters and platform modules

Performance Comparison of Floater Materials

| 材料 | Strength | Corrosion Resistance | UV Resistance | Cost | Service Life | Application Fit |

|---|---|---|---|---|---|---|

| 高密度ポリエチレン | Medium | ★★★★★ | ★★★★★ | ★★☆☆☆ | 20–25 years | General FPV |

| PP | High | ★★★★☆ | ★★★☆☆ | ★★☆☆☆ | 15–20 years | Specific components |

| FRP | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★☆ | 25+ years | Offshore/special |

| Aluminum | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★★☆ | 25+ years | Premium projects |

| Steel | ★★★★★ | ★★☆☆☆ | ★★★☆☆ | ★★★★☆ | Depends on protection | Extreme environments |

| Composite | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★☆☆ | 20–25 years | Special structures |

Material Selection Recommendations by Application Scenario

1. Reservoirs and Lakes (Typical FPV Sites)

Recommended: HDPE, composite floaters

Reason: Reliable, economical, mature, broadly adaptable

2. Fishery–Solar Hybrid Projects

Recommended: HDPE, PP

Reason: Lightweight, environmentally friendly, minimal impact on aquaculture

3. Offshore or Highly Corrosive Environments

Recommended: FRP, aluminum alloy, steel floaters

Reason: High resistance to salt spray, waves, and corrosion

4. Cold-Climate Regions

Recommended: Low-temperature HDPE, FRP

Reason: Prevent brittleness and structural cracking

Future Trends in Floater Materials

With the continuous advancement of FPV technology, floater materials are evolving toward:

- High-performance modified plastics

Enhanced UV and oxidation resistance for longer service life. - Hybrid/composite structures

Combining plastics, metals, and foam to improve overall strength and durability. - Eco-friendly and recyclable materials

Aligning with global sustainability goals. - Modular, integrated designs

Tighter integration with PV mounting structures to improve installation efficiency and reliability. - Wave-resistant engineering improvements

Meeting the demands of larger FPV installations and offshore deployments.

Floater materials form the foundation of floating solar power plants, directly affecting safety, long-term reliability, and overall project economics. Selecting an appropriate floater material requires consideration of environmental conditions, climate, target lifespan, and cost expectations.

As more countries expand their renewable energy portfolios, floating solar will continue to grow in scale. Floater technologies will likewise evolve—offering safer, more durable, and more efficient solutions for water-based PV installations.

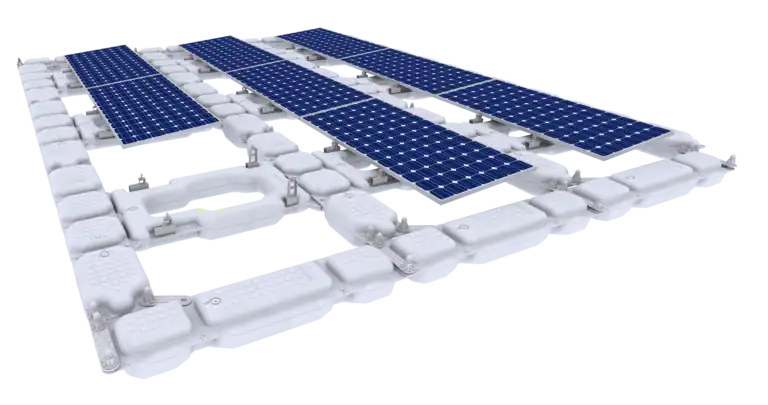

Floating: Aqua FPV

Built with high-density polyethylene (HDPE), Soeasy Solar Aqua FPV system delivers reliable performance for a wide range of water-based PV applications. Its modular configuration allows for quick installation and flexible layout design across lakes, ponds, and reservoirs. Combining material durability with practical engineering, Aqua FPV provides a stable and adaptable solution that supports long-term operation in floating solar projects.

English

English