Standing seam metal roofs have become one of the most popular choices for commercial and industrial photovoltaic (PV) projects due to their durability, high structural strength, and the ability to achieve a “zero-penetration” installation. Their design naturally aligns with solar mounting systems, allowing for safe, fast, and cost-efficient PV installation without compromising roof integrity.

As a professional solar mounting solution provider, Soeasy Solar offers multiple mature installation systems specifically developed for standing seam metal roofs. This guide covers roof structure features, mainstream installation methods, construction steps, and quality control practices to help ensure a reliable and long-lasting PV installation.

Advantages of Installing PV Systems on Standing Seam Metal Roofs

Standing seam metal roofs are constructed from interlocked vertical seams, typically ranging from 25 mm to 65 mm in height. The mechanically seamed design forms a continuous waterproof surface with excellent structural stability.

Why standing seam roofs are ideal for PV installation:

- Zero penetration: PV clamps attach directly to the seams without drilling, preserving the waterproof layer.

- High strength and long lifespan: Metal roofs can last 30–50 years, aligning well with the lifecycle of PV power plants.

- Wide compatibility: Suitable for factories, logistics centers, commercial buildings, schools, and other large-span roofs.

- Efficient installation: Clamps install quickly and easily, reducing labor costs and construction time.

Main Installation Methods for Standing Seam Solar Mounting Systems

To accommodate different roof types and engineering requirements, the industry commonly uses the following installation methods:

1. Standing Seam Clamps

These are the fundamental components of all standing seam rooftop PV systems.

Features:

- Made primarily from AL6005-T5 aluminum, offering lightweight strength and corrosion resistance.

- Paired with SUS304 stainless steel bolts to ensure long-term stability.

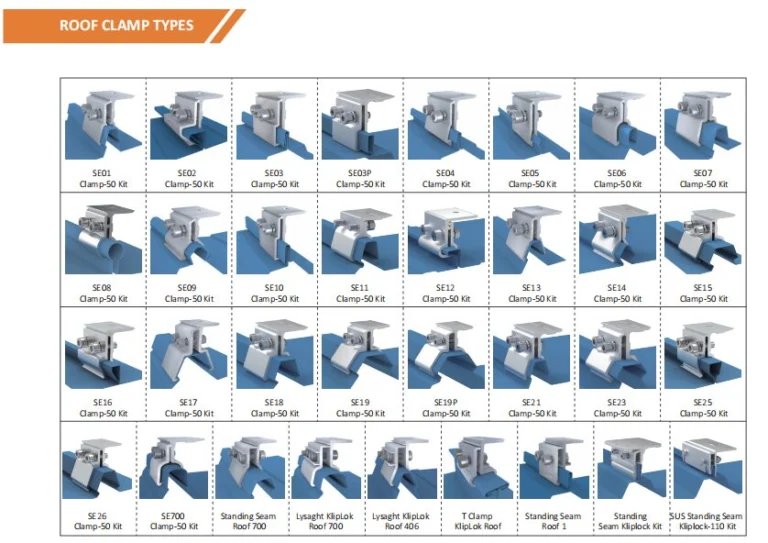

- Compatible with multiple seam types, including:

- 360° double-lock seams

- Vertical rib seams

- Snap-lock seams

- Double-standing seams

The clamp grips the seam using set screws, without damaging the metal panel or compromising waterproofing.

2. Rail-Based Mounting Systems

Aluminum rails are connected to the clamps, forming a stable and widely used solution.

Advantages:

- High flexibility in layout

- Strong load-bearing capacity, suitable for high-wind or heavy-snow regions

- Easier module alignment

- Excellent engineering adaptability

This system is commonly used for large-scale commercial projects.

3. Rail-less Mounting Systems

PV modules are directly connected to the clamps via special hardware.

Advantages:

- Lightweight system design

- Lower material cost

- Faster installation

Ideal for simple and medium-sized rooftop systems.

Pre-Installation Assessment and Preparation

A high-quality PV system begins with thorough site evaluation.

1. Roof Structural Assessment

- Roof panel thickness and strength

- Seam type and spacing

- Overall structural load capacity (dead load + live load)

- Corrosion level and maintenance history

2. Environmental Load Analysis

- Wind uplift

- 雪荷重

- Seismic conditions

- Surrounding shading and roof height

Professional engineering calculations are essential for system safety.

3. Module Layout and System Design

- Module orientation (south recommended; east-west as an alternative)

- Row spacing and array configuration

- Lightning protection and grounding planning

- Cable routing and management

Detailed Installation Steps for Standing Seam Metal Roof PV Systems

1. Installing the Standing Seam Clamps

- Clean the seam and surrounding area

- Position clamps according to design spacing

- Tighten the stainless-steel set screws with a torque wrench

- Ensure clamps are secure, stable, and non-deforming

Note: Avoid over-tightening to prevent seam damage.

2. Installing the Rail System (If Applicable)

- Connect rails to clamps via adapters

- Adjust rails for straightness and levelness

- Ensure smooth alignment at rail splice points

- Maintain rail spacing according to module size

3. Installing a Rail-less System

- Connect modules directly to clamps or adapters

- Maintain consistent spacing between modules

- Ensure clamp strength meets wind uplift requirements

4. PV Module Installation

- Secure modules with mid and end clamps

- Tighten according to specified torque

- Leave sufficient cable clearance to avoid friction with the roof surface

5. Grounding and Lightning Protection

- Install grounding clips and copper grounding bars

- Bond modules and rails together using grounding jumpers

- Conduct lightning protection evaluation for high-rise structures

Safety and Quality Control

- Follow all rooftop safety protocols

- Avoid welding, drilling, or any operation that may damage the roof

- Tighten all bolts to specified torque and keep records

- Conduct a full post-installation inspection:

- Module fastening

- Clamp and rail connections

- Grounding system integrity

- Array alignment and appearance

Operation, Maintenance, and Lifecycle Management

Standing seam rooftop PV systems generally require minimal maintenance, but regular inspections are still recommended:

- Annual inspection of clamp and rail tightness

- Check for any loose bolts or clamp slippage

- Clear accumulated dust, leaves, or debris

- Inspect roof corrosion conditions

- Routine checks of cables, connectors, and grounding systems

Proper maintenance extends system life and ensures stable power generation.

SOEASY Solar: What Can We Do For You?

Standing seam metal roofs, with their structural stability and zero-penetration installation method, offer one of the best foundations for rooftop PV systems. Choosing the right professional installation solution ensures long-term safety, cost-effectiveness, and reliable performance.

Soeasy Solar has long been dedicated to the development of distributed PV mounting solutions, providing safe, reliable, and highly compatible rooftop systems for global customers. Our products are specifically designed for standing seam, Kliplok, and Lysaght-type metal roofs. Whether you require rail-based or rail-less systems, we offer customized design and technical support to guarantee the best performance from installation to long-term operation.

Click here to see our solutions for standing seam metal roofs

English

English