Material Selection in the Coastal Corrosive Challenge

The operational lifespan of a solar power mounting structure is intrinsically linked to its ability to withstand its environment. Coastal sites, characterized by salt mist, high humidity, and UV exposure, present a uniquely aggressive corrosive cycle. This technical note provides a detailed comparison of two steel coating technologies—Hot-Dip Galvanized (HDG) and Zinc-Aluminum-Magnesium (ZnAlMg)—specifically under the duress of coastal conditions.

Coastal Corrosion Mechanisms & Material Response

The primary corrosive agent in coastal air is chloride salt. It destroys protective oxide layers and facilitates rapid electrochemical corrosion.

1. Hot-Dip Galvanized (HDG) in Coastal Environments

- Corrosion Progression: The zinc coating corrodes sacrificially at an accelerated rate. The primary corrosion product, zinc hydroxide chloride, is somewhat soluble and can be washed away by rain, exposing fresh zinc to further attack.

- Cut-Edge & Scratch Response: The sacrificial protection is localized. On a cut edge, the protection zone is limited, leaving the exposed steel core vulnerable. Once the thin zinc layer at the edge is consumed, rust initiates and can undercut the adjacent coating.

- Long-Term Outlook: The protection duration is a direct function of zinc coating thickness. In a high-chloride environment (C5-M per ISO 12944), the rate of zinc consumption is high, which can dictate a thicker, heavier coating to achieve a target design life.

2. Zinc-Aluminum-Magnesium (ZnAlMg) in Coastal Environments

- Corrosion Progression: The alloy coating provides a multi-phase response. The aluminum contributes to a dense, adherent barrier layer, while zinc and magnesium offer active protection. The key differentiator is the formation of stable, insoluble corrosion products (e.g., simonkolleite and hydrozincite).

- Cut-Edge & Scratch Response: The “self-healing” phenomenon refers to the ability of these stable corrosion products to migrate and form a protective, dense layer over the exposed steel, effectively passivating the surface and drastically slowing the corrosion rate at the defect site.

- Long-Term Outlook: The combination of barrier protection and the formation of a stable, protective patina leads to a lower corrosion rate over time compared to pure zinc, potentially allowing for a thinner coating to achieve an equivalent design life in the same environment.

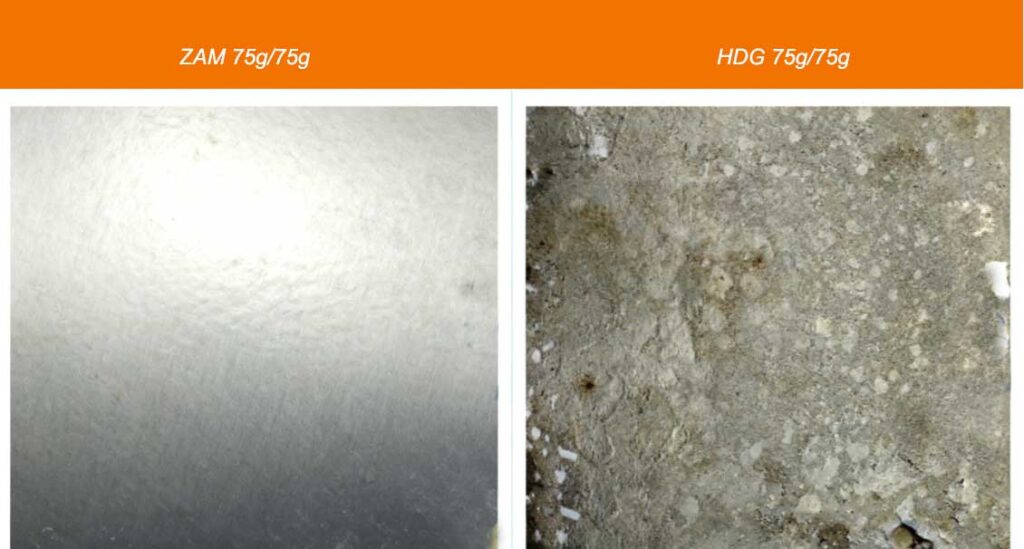

Comparison of the corrosion resistance of zinc-aluminum-magnesium and hot-dip galvanized under the same conditions

Comparison of zinc-aluminum-magnesium and hot-dip galvanizing under neutral salt spray test conditions

Comparative Technical Profile for Coastal Applications

| Analysis Parameter | Hot-Dip Galvanized (HDG) | Zinc-Aluminum-Magnesium (ZnAlMg) |

|---|---|---|

| Primary Protection | Sacrificial (Cathodic) | Barrier + Sacrificial |

| Coating Consumption in Salt Mist | Linear; rate depends on chloride deposition. | Non-linear; initial rate slows as stable patina forms. |

| Behavior at Cut Edges | Protection zone limited to ~2mm. Rust progression is linear from the edge. | Protective layer forms on bare steel, slowing rust progression. |

| Corrosion Product | Zinc Hydroxide Chloride (often soluble). | Stable Zinc/Magnesium Carbonates & Hydroxides (insoluble). |

| Surface After Weathering | Dull grey, may exhibit localized “white rust” or red rust. | Dull grey, uniform patina. More uniform appearance. |

Conclusion: A Matter of Mechanism, Not Merit

The selection between Hot-Dip Galvanized and Zinc-Aluminum-Magnesium for a coastal solar racking system is not a simple declaration of superiority. It is a technical decision based on the project’s design philosophy, lifespan requirements, and environmental load analysis.

- Hot-Dip Galvanized (HDG) provides robust, time-tested sacrificial protection. Its performance in coastal environments is predictable and is a function of coating mass.

- Zinc-Aluminum-Magnesium (ZnAlMg) employs a composite mechanism that combines barrier and sacrificial protection, resulting in a different corrosion progression profile, particularly noted for its effectiveness on cut edges and scratches.

A precise evaluation should reference international standards for corrosivity (e.g., ISO 12944 C5-M) and consider long-term performance data from salt spray tests and real-world exposures to inform the final specification for marine-grade solar structures.

Selection Framework: Project Environment & Budget Considerations

The final specification for a solar mounting structure must balance technical performance with financial feasibility. The choice between HDG and ZnAlMg is not merely a technical one; it is a strategic decision influenced by specific project parameters.

The following framework outlines key considerations to guide the selection process:

1. Project-Specific Environmental Load:

- Direct Oceanfront vs. Inland Coastal: The concentration of salt aerosols decreases dramatically with distance from the shoreline. A site 50 meters from the high-tide line imposes a significantly harsher load than one 5 kilometers inland.

- Wave Splash Zone: Projects on structures like piers are subject to direct saltwater splash, representing the most severe condition.

2. Design Lifespan & Performance Warranty:

- Project Lifespan: A project financed for a 25-year operation has different durability requirements than one with a 15-year horizon. The material must be selected to confidently last the entire operational period with minimal intervention.

- O&M Budget & Strategy: Consider the long-term cost and feasibility of inspections, maintenance, and potential component replacement. A lower initial investment might be offset by higher future maintenance liabilities.

3. Financial Structure & Budget Model:

- Initial CAPEX vs. Total Cost of Ownership (TCO):

- Hot-Dip Galvanized (HDG) typically presents a lower initial capital expenditure (CAPEX), which can be a decisive factor for tightly budgeted projects.

- Zinc-Aluminum-Magnesium (ZnAlMg), while often involving a higher initial cost, is designed to minimize maintenance and replacement risks, potentially yielding a lower Total Cost of Ownership (TCO) over the asset’s lifetime.

- Financing Requirements: Projects requiring long-term bank financing or adhering to strict ESG (Environmental, Social, and Governance) principles may benefit from the reduced risk profile and demonstrable long-term durability offered by advanced material specifications.

Decision Workflow:

| If your project is… | Consideration leans towards… | Primary Rationale |

|---|---|---|

| In a moderate coastal zone (>1km inland) with a sub-20-year design life and a highly CAPEX-constrained budget. | Hot-Dip Galvanized (HDG) | Achieving performance requirements with the most direct cost control on initial investment. |

| In a severe coastal zone (direct front or splash zone) with a 25+ year design life, or where minimizing long-term O&M is a critical priority. | Zinc-Aluminum-Magnesium (ZnAlMg) | Mitigating long-term risk and maximizing structural integrity over the full project lifespan, optimizing TCO. |

Ultimately, the most cost-effective and technically sound choice is determined by a lifecycle cost

Contact SoEasy Solar Today to receive a detailed project analysis and a customized specification for the most reliable and cost-effective solar mounting structure for your coastal environment.

English

English