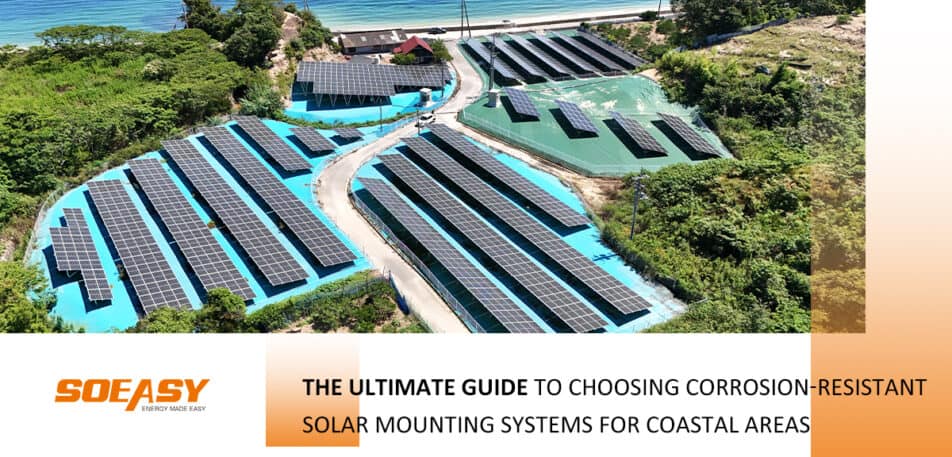

For solar energy investors, EPCs, and project developers, coastal regions represent a prime location for harnessing the sun’s power. However, the very environment that offers abundant sunlight also presents a significant challenge: relentless corrosion from salt, moisture, and wind.

Choosing the wrong solar mounting structure can lead to premature failure, costly maintenance, and a compromised return on investment. This guide will walk you through the critical factors for selecting the most durable and corrosion-resistant solar mounting system for your coastal photovoltaic project.

Understanding the Enemy: Why Coastal Corrosion is a Major Threat

Coastal atmospheres are saturated with salt mist and chlorides. When these particles settle on metal surfaces, they accelerate the corrosion process, leading to rust and structural degradation. Standard, untreated carbon steel solar mounts can begin to show signs of failure in just a few years in such aggressive environments.

The key to longevity lies in selecting materials and protective coatings specifically engineered to withstand these conditions.

Key Material Choices for Coastal Solar Mounting Systems

When evaluating solar mounting structures for high-corrosion zones, you have two primary, proven choices:

1. Aluminum Solar Mounting Systems

- Inherent Corrosion Resistance: Aluminum naturally forms a protective oxide layer when exposed to air, which self-repairs if scratched. This makes it highly resistant to salt-induced corrosion.

- Advantages: Lightweight, strong, and maintenance-free. It does not require a protective coating, meaning its performance won’t be compromised by surface damage.

- Best For: Rooftop installations where weight is a concern, and in extremely aggressive environments where long-term, zero-maintenance performance is critical.

2. Hot-Dip Galvanized (HDG) Steel Solar Structures

- Superior Protective Coating: steel is dipped in molten zinc, creating a thick, metallurgically bonded coating that provides both a physical barrier and sacrificial (cathodic) protection. Even if scratched, the zinc corrodes first, protecting the underlying steel.

- Advantages: Offers exceptional strength and durability at a lower cost than all-aluminum systems. It is the industry standard for robust, corrosion-resistant ground mounts.

- Critical Specification: For coastal areas, ensure a heavy galvanized coating with a minimum thickness of 550 g/m² or 10µm.

3. The Role of Stainless Steel Components

For critical fasteners, bolts, and connectors, stainless steel is non-negotiable. Specifically, you should insist on:

- A4 (316) Stainless Steel: The minimum standard for coastal environments, offering excellent resistance to chlorides.

- A5 (Duplex 2205) Stainless Steel: For highly aggressive salt-laden environments, this grade provides superior strength and pitting resistance.

Using standard, non-stainless fasteners is a common point of failure that can jeopardize the entire structure.

Beyond the Base Material: Critical Selection Criteria

1. Certification and Testing – The Proof of Performance

The most critical test is the Salt Spray Test (ASTM B117). A high-quality coastal-grade solar mount should withstand 1,000 to 1,500 hours of salt spray testing with no red rust formation on the base material.

2. Design and Engineering for Coastal Winds

Coastal areas are often prone to high winds. The mounting system must be engineered for these loads. Look for systems that have undergone independent structural load calculations and wind tunnel testing.

3. Compatibility and Ease of Installation

A well-designed system minimizes on-site drilling and cutting, which can expose raw metal edges and compromise corrosion resistance. Pre-assembled, bolt-together designs are ideal.

SOEASY solar pre-assembled brackets, increasing construction efficiency by 40-50%

Comparison Table: Aluminum vs. Hot-Dip Galvanized Steel for Coastal Use

| Feature | Aluminum Solar Racks | Hot-Dip Galvanized Steel Racks |

|---|---|---|

| Corrosion Resistance | Excellent (Inherent) | Excellent (Coating-Dependent) |

| Strength-to-Weight | Very High | High |

| Cost | Higher | More Cost-Effective |

| Longevity in Coastal | 25+ Years | 25+ Years (with proper coating) |

| Maintenance | Virtually Zero | Virtually Zero |

| Ideal Application | Rooftops, High-Salt Zones | Large-Scale Ground Mounts |

Conclusion: Partner with a Specialist Manufacturer

Your choice of a solar mounting structure will define the resilience and profitability of your coastal solar project for decades. Don’t compromise.

As a leading photovoltaic bracket manufacturer specializing in corrosion-resistant solutions, we provide certified, engineered mounting systems built to endure the harshest coastal environments. Our products undergo rigorous ASTM B117 salt spray testing to guarantee performance.

Ready to secure your investment? Contact us today for a custom quote and to review our third-party test certificates. Let us help you build a solar project that stands strong against the sea.

English

English