In residential and C&I (Commercial and Industrial) distributed solar projects, pitched roofs are prime real estate for energy generation. However, for EPC (Engineering, Procurement, and Construction) contractors, the real challenge isn’t the modules themselves—it’s the structural layer and tiling logic hidden beneath the surface.

Whether it’s ceramic, asbestos, asphalt, or color steel tile, each roof type demands a unique load-bearing model and waterproofing strategy. Here is a professional breakdown of the underlying logic for PV mounting system design.

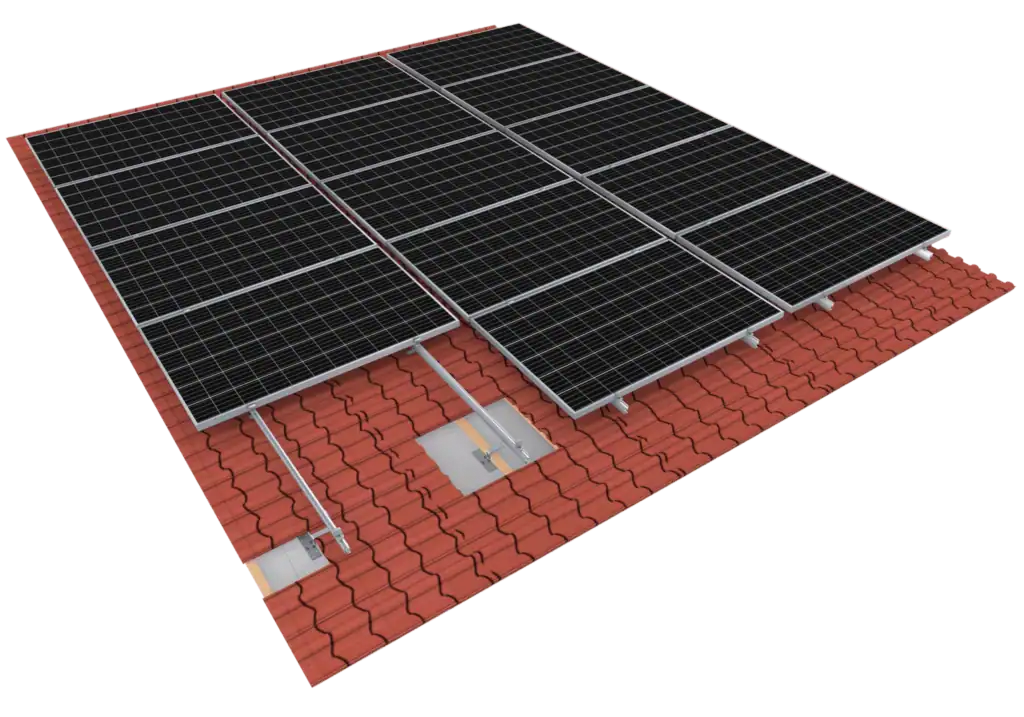

1. Ceramic Tile Roofs: The “Invisible Skeleton” Battle

- Scenarios: Private villas, urban renovations, high-end residential areas.

- Characteristics: High aesthetic value, brittle material, multi-overlap joints.

The golden rule for ceramic tiles? Zero load-bearing. The mounting system must penetrate the tile to find the true support point below.

Structural Solutions:

- Wooden Purlins: Older wood can rot or strip screws. Strategy: Use adjustable stainless steel roof hooks. Hooks must straddle the wooden beam using full-thread wood screws with pre-drilled holes to prevent splitting.

- Concrete Decks: It is difficult to align drill holes with tile gaps. Strategy: Use concrete pillars with custom flashing. Remove the tile, install chemical anchors into the concrete, add a metal flashing plate, and reseal with the original or new tile.

- Steel Frames: The easiest to manage. Fix aluminum rails directly to steel beams via self-tapping screws, treating the tiles as a decorative layer only.

2. Asbestos Tile Roofs: Flexible Decoupling for Brittle Surfaces

- Scenarios: 80s-90s factories, agricultural warehouses, temporary buildings.

- Characteristics: Extremely brittle, low load capacity, high cracking risk.

Asbestos (or fiber cement) tiles are high-risk zones. Traditional “clamping” methods often lead to catastrophic cracking and leakage.

Professional Logic: “Bridge the Tile, Don’t Press It”

The mounting posts must pass through the tile and rest directly on the steel purlins or concrete beams.

- Execution: Install curved aluminum waterproof gaskets above and below the entry point. The gasket’s curvature must match the tile corrugation perfectly to distribute pressure and seal the opening.

- Component Choice: Avoid flat clamps. Use adjustable U-bolts or extended hooks to ensure the force-bearing point is entirely decoupled from the tile body.

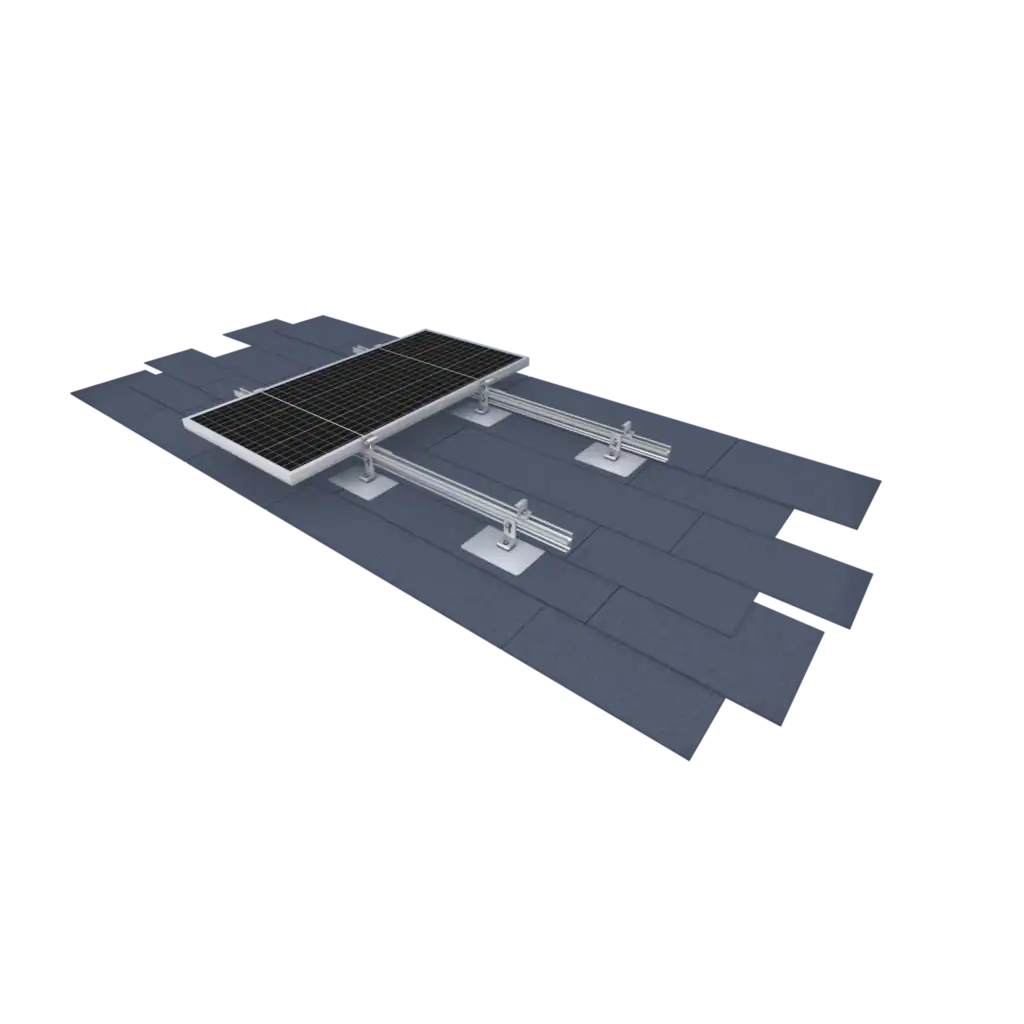

3. Asphalt Shingle Roofs: Precision Overlap (North American Standard)

- Scenarios: North American-style villas, high-end resorts.

- Characteristics: Flexible, granular surface, integrated waterproofing, prone to aging.

The B2B Focus: Waterproofing Longevity

On asphalt shingle roofs, structural integrity and waterproofing lifespan are equally critical.

- Wooden Substructures (OSB/Plywood): The optimal solution is the L-foot flashing mount. Gently lift the shingle, place the flat mount on the baseboard, secure it to the rafter with lag bolts, and lay the shingle back down. This ensures no exposed holes and zero leakage risk.

- Mechanical Compensation: Since shingles are usually laid over thin boards, screws must bite into the rafters. Limit rail spans to 1.2m to prevent local roof deformation.

4. Color Steel Tile Roofs: High-Speed Industrial Delivery

- Scenarios: Logistics warehouses, steel structure plants, manufacturing hubs.

- Characteristics: Metal material, clear mechanical properties, integrated structure.

This is the most standardized segment of the PV market. Success here depends on clamp compatibility and waterproofing warranties.

Mainstream Approaches:

- Standing Seam/Kliplok: No penetration required. Use specialized aluminum clamps to “bite” onto the ribs.

- Pro Tip: Verify the rib shape (trapezoidal vs. rounded). Use dual-sided anti-slip clamps with vibration-resistant screws.

- Trapezoidal (Corrugated) Metal: Requires penetration at the crest.

- Pro Tip: Use 304 stainless steel self-tapping screws with EPDM waterproof washers. Tightening torque must be precise; too loose causes leaks, too tight crushes the washer.

Professional Fit Over Universal Mounting

For a B2B solar enterprise, each roof type tests a different core competency:

- Ceramic: Civil repair and finishing.

- Asbestos: Structural avoidance logic.

- Asphalt: Waterproofing detail.

- Color Steel: Supply chain efficiency and precision.

Professional mounting isn’t just about “putting panels up”—it’s about understanding the 10cm of structure beneath the tile. Only by speaking the mechanical language of the roof can you design a system that lasts 25 years.

Looking for a custom load-calculation or specific junction details for your next project? Contact our technical support team for a tailored mounting solution.

English

English