Why Installation Efficiency Matters in Solar Projects

In solar power plant construction, time represents more than just schedule progress—it directly influences project return on investment (ROI). Every phase of a PV project, from system design and procurement to installation and grid connection, affects both capital costs and revenue generation.

Among these stages, mounting system installation typically accounts for 30%–50% of the total project duration. Any improvement in installation efficiency therefore has a direct and measurable impact on project cash flow, labor cost control, and commissioning timelines.

Traditional mounting systems rely heavily on on-site assembly of numerous individual components. This approach often creates bottlenecks due to complex workflows, high labor dependence, and limited schedule predictability. In projects with challenging terrain, harsh weather conditions, or tight deadlines, on-site assembly frequently becomes the critical constraint on overall project progress.

What Is a Pre-Assembled Solar Mounting System?

A pre-assembled solar mounting system refers to a solution in which part or all of the structural assembly takes place in a controlled factory environment before delivery to the site. Manufacturers ship these systems as standardized units that installers can position and fix directly on-site.

Depending on the level of pre-assembly, systems generally fall into three categories:

- Component-level pre-assembly

Examples include welded posts or beams with pre-installed connectors. - Module-level pre-assembly

Partial structural rows assembled with rails and clamps. - Structural unit-level pre-assembly

Complete frameworks such as solar carport structures or rooftop triangular mounting units.

Pre-assembled systems suit a wide range of PV applications. They deliver the greatest value in projects that demand fast installation, enhanced on-site safety, or simplified construction under constrained conditions.

Time Cost Analysis of Traditional On-Site Assembly

Conventional mounting installation requires installers to handle dozens of separate components and complete multiple steps on-site, including sorting, positioning, fastening, and leveling. This process introduces several time-related challenges:

- Complex workflows

Multiple assembly steps increase dependency on material management and tool coordination. - High reliance on skilled labor

Accurate measurement and adjustment require experienced installers, while less-trained crews often work more slowly and make more errors. - Alignment errors and rework

Wind, uneven terrain, or site constraints frequently cause installation deviations that require time-consuming corrections. - Low schedule predictability

Parallel tasks and weather sensitivity make it difficult to control daily installation output with precision.

Together, these factors limit scalability and slow down large or time-sensitive projects.

How Pre-Assembled Mounting Systems Reduce Installation Time

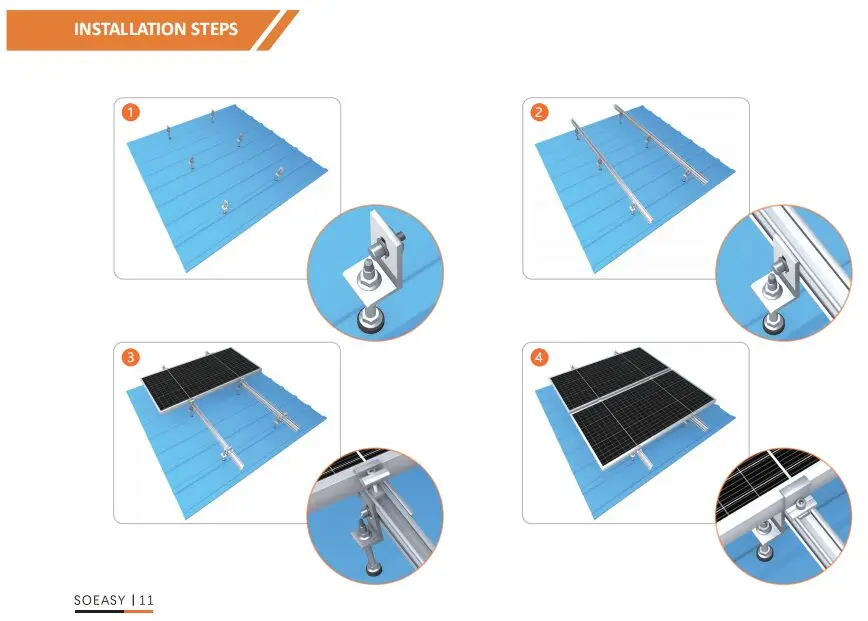

1. Fewer On-Site Installation Steps

Pre-assembled systems shift critical structural connections—such as post-to-beam joints and rail fixing—from the site to the factory. On-site crews focus mainly on positioning, foundation fixing, and unit-to-unit connections.

This approach can reduce on-site installation steps by more than 40%, significantly simplifying construction workflows.

2. Lower Dependence on Specialized Labor Skills

Standardized design and factory pre-alignment turn installation into a repeatable process of “position and fasten.” Installers no longer need to perform cutting, welding, or complex measurements on-site.

After basic training, new crew members can quickly reach stable productivity levels, allowing project managers to allocate labor more flexibly and scale teams efficiently.

3. Improved Installation Accuracy and Consistency

Factory assembly relies on jigs, fixtures, and dimensional inspections to ensure uniform angles and tolerances. This controlled environment minimizes cumulative errors before delivery.

As a result, on-site installation achieves higher consistency across arrays, largely eliminating time-consuming rework and adjustment.

4. Shorter Installation Time per Mounting Unit

Pre-assembled systems can reduce on-site installation time per mounting unit or row by 50%–70%. In large-scale projects, this advantage compounds rapidly and leads to substantial reductions in total construction duration.

For utility-scale ground-mounted plants, especially those exceeding 100 MW, pre-assembly enables fast, repetitive installation at scale.

Application-Specific Benefits of Pre-Assembled Design

Rooftop Solar Projects

Rooftop installations often involve limited space and strict safety requirements. Pre-assembled mounting units reduce working-at-height time and lower personnel exposure to risk.

Modular units also simplify hoisting and positioning, allowing overall construction schedules to shorten by more than 30%.

Ground-Mounted Solar Plants

Large ground-mounted projects can deploy segmented pre-assembled structures and support parallel installation by multiple teams. Crews can begin installation immediately upon delivery, achieving predictable daily output.

In sites with regular terrain, daily installation capacity often increases by two to three times compared with traditional methods.

Solar Carport Projects

For solar carports, manufacturers can pre-assemble columns, beams, and waterproof structures into complete frames. On-site crews mainly perform lifting and anchoring.

This method accelerates installation while ensuring overall structural integrity and reducing long-term maintenance risks.

Additional Project Management Benefits

Beyond faster installation, pre-assembled mounting systems offer several management advantages:

- Higher schedule controllability

Stable installation rhythms enable precise construction planning. - Optimized total project cost

Shorter on-site duration lowers labor, equipment rental, and supervision costs. - Improved delivery reliability

Reduced dependence on weather and labor availability increases on-time project completion rates.

Balancing Pre-Assembly Level with Transportation and Site Conditions

The optimal level of pre-assembly depends on logistics and site constraints:

- Highly pre-assembled units require more transport volume and suit projects near manufacturing facilities or with good access roads.

- Medium or complex sites benefit from component-level or module-level pre-assembly, which balances efficiency and logistical flexibility.

- During the design phase, teams should clearly define the division of work between factory and site to ensure seamless integration with foundations, cable routing, and civil works.

Key Factors When Selecting a Pre-Assembled Mounting System

When evaluating pre-assembled solutions, project owners and EPCs should consider:

- Project scale and schedule

Large or time-critical projects gain the most from higher pre-assembly levels. - Site conditions

Assess access, lifting capacity, and on-site storage space. - System standardization

Choose systems with unified interfaces and strong compatibility to support rapid deployment. - Supplier experience

Verify proven capabilities in pre-assembly design, mass production, and logistics coordination.

Pre-Assembled Systems as a Strategic Efficiency Upgrade

Pre-assembled solar mounting systems transfer a significant portion of installation work from the variable site environment to a controlled factory setting. This shift shortens construction cycles, reduces human error, and improves overall execution predictability.

For solar projects that prioritize fast delivery and precise cost control, pre-assembled systems represent more than a technical improvement—they serve as a strategic tool to enhance competitiveness and investment returns.

As the PV industry continues to pursue lower levelized cost of energy (LCOE) and higher standardization, mounting solutions with mature pre-assembly design and large-scale delivery capabilities will play an increasingly important role in enabling high-quality, rapid solar plant construction.

Looking to Improve Your Project Installation Efficiency?

Contact us to explore customized pre-assembled mounting solutions and professional project evaluation support tailored to your specific site conditions and schedule requirements.

English

English